Plywood Veneer Dryer Machine Cost

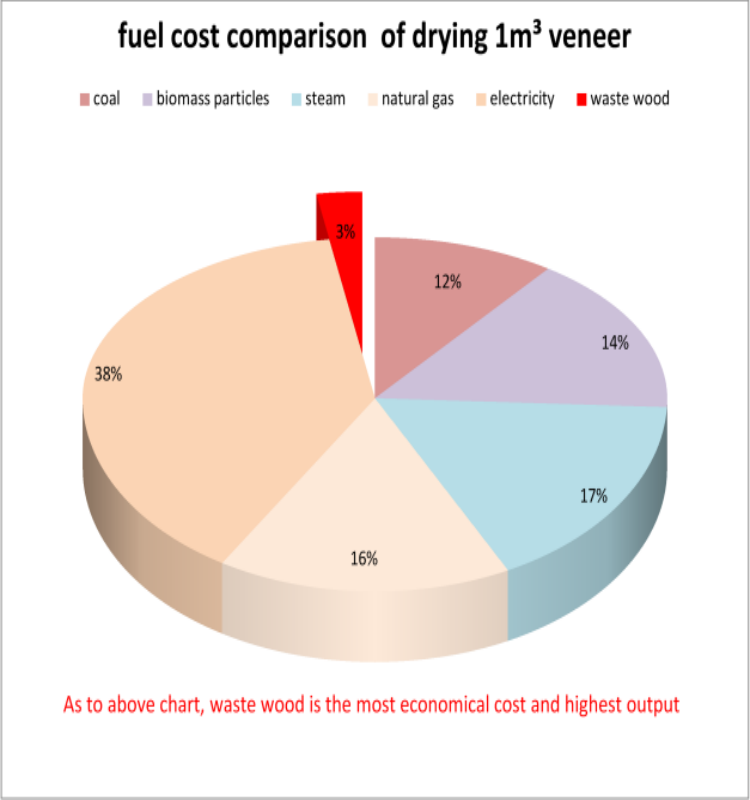

Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. The composite cost is only about $6-12/cubic meter, which can improve customers profit space greatly.

Price

$90,000.00

Product Details

Plywood Veneer Dryer Machine Cost

Veneer drying is one of the most crucial phases of veneer production.The main objective of the drying process is to produce high-quality optimally dried veneer sheets with the highest possible efficiency.This is carried out by removing water from the sheet and decreasing moisture content to an optimized level by using hot and humid air inside a dryer.By choosing industrial veneer drying, you improve veneer quality with uniform drying result.As a result, you get high-quality.Its robust and sturdy structure guarantees a long lifetime and steady production with high efficiency.The proven technology gives you advanced production efficiency and capacity.

Advantages of Veneer Drying Machine

1.The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

2.The veneer after drying is free of splits and the surface is in good condition for gluing.

3.Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

4.Shine veneer dryer is equipped with automatic control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are international famous brands.

5.Shine veneer dryer adopts frequency conversion, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve an ideal drying effect.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 48 | 52 | 56 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Total power (kw) | 154 | 169 | 180 | 198 | 209 |

Overall size LxWxH(m) | 44*4.5*2.27 | 48*4.5*2.27 | 52*4.5*2.27 | 56*4.5*2.27 | 60*4.5*2.27 |

Customer Case

Certificate And Exhibition

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close