Roller Type Veneer Drying Machine

roller veneer dryer is a new generation wood veneer drying machine. It adopts the latest international pressure contact veneer drying technology to ensure the veneer is heated evenly. It can be used to dry rubber wood, eucalyptus, birch, teak, all kinds of hard wood and soft wood veneer etc.

Shine roller veneer dryer has the advantages of simple operation, safety and practicality, stable operation and easy maintenance. The processes of hot pressing-leveling-drying are finished at the same time.The veneer after drying is flat, smooth and without marks and the moisture content is uniform.

Product Details

Product Description of Veneer Drying Machine

Shine veneer drying machine has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect.veneer drying machine can dry veneers of various thickness and various moisture contents.The quality of wood veneer dryer directly affects the quality of veneer and glued products. The design of hot air continuous roller press is based on the most advanced continuous pressure contact veneer drying technology in the world. Our biomass burner as patent products,which can use waste wood as fuel and burn all kinds of waste wood directly to reduce fuel cost to the most.Veneer dryers machine offers great advantages over conventional veneer drying systems.

4deck veneer drying machine in Latvia scene

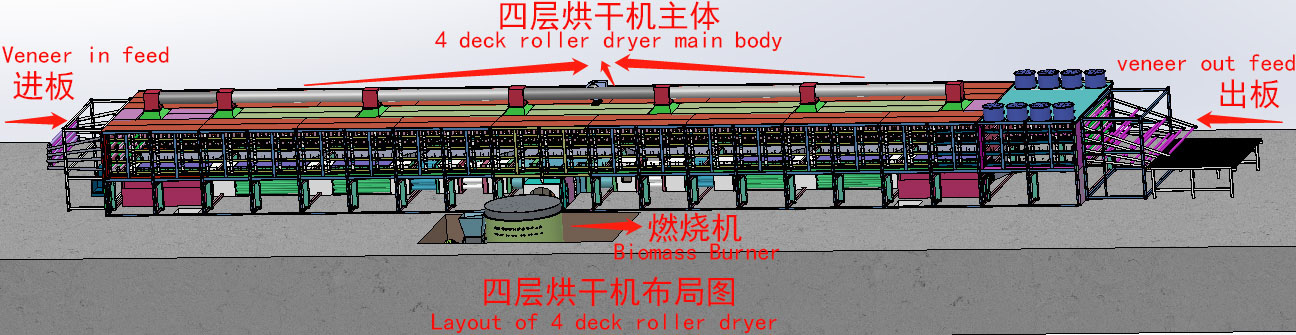

4 deck veneer drying machine

Biomass Burner

layout of 4 deck roller veneer dryer

Features:

1.The machine is the main apparatus in plywood industry.

2. It uses to remove moisture from the veneer.

3.The heat medium can be thermo oil and heat steam.

4.The whole machine can be divided into two parts: heating section and cooling section.

5.It includes mesh type, roller type, mesh&roller type, could be customized according to your requirements.

viedo in customer scene

veneer dryer video of Myanmar customer factory

Product Parameters

Parameter Model |

DHS20M

| DHS22M | DHS24M | DHS26M | DHS28M | DHS30M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 | 4 | 4 |

Veneer thickness(mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Heating area (m)

| 16 | 18 | 20 | 22 | 24 | 26 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | About 3 | About 3.3 | About 3.6 | About 4 | About 4.4 | About 4.8 |

Heat exhaustion(10000 kcal/h) | About 105 | About115 | About126 | About140 | About 154 | About168 |

Total power (kw) about | 105 | 110 | 115 | 120 | 125 | 130 |

Overall size LxW(m) | 31*5.5 | 33*5.5 | 35*5.5 | 37*5.5 | 39*5.5 | 41.*5.5 |

Customer Case

Customers from Malaysia Visit

Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close