Shine 4-deck 32 meter roller veneer dryer

Energy Efficiency: The design of a 4-deck roller veneer dryer allows for efficient heat distribution, reducing energy consumption and operating costs in the long run.

Versatility: With four decks, operators have the flexibility to adjust drying parameters on each deck independently, allowing for different drying treatments based on the specific requirements of different types of wood veneer.

Product Details

Product advantages and feature

Increased Capacity: The multiple decks in a 4-deck roller veneer dryer allow for higher production throughput compared to dryers with fewer decks, making it suitable for larger volume production.Uniform Drying: The use of multiple decks ensures that the veneer is dried evenly and consistently across all layers, resulting in a higher quality end product with fewer defects. Overall, a 4-deck roller veneer dryer offers increased capacity, uniform drying, energy efficiency, versatility, space-saving design, and enhanced control, making it a valuable asset for woodworking operations aiming for high-quality, efficient veneer drying processes.

Main technical and parameter

Parameter Model | DHS34m | DHS36m | DHS38m | DHS40m |

Heating area(m) | 30 | 32 | 34 | 36 |

Working Width(m) | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 |

Veneer thickness (mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Veneer water moisture | Fresh Veneer to about 5% | Fresh Veneer to about 5% | Fresh Veneer to about 5% | Fresh Veneer to about 5% |

Drying capacity (m³/day) | About 4.4 cbm | About 4.7 cbm | About 4.96 cbm | About 5.25 cbm |

Total Power | 166KW | 174KW | 182KW | 190KW |

Actual electricity consumption | About 116kwh per hour | About 121kwh per hour | About 127kwh per hour | About 133kwh per hour |

Overall Dimension(L*W) | 38m×5m | 40m×5m | 42m×5m | 44m×5m |

Certification

CustomerVisiting

Exhibition

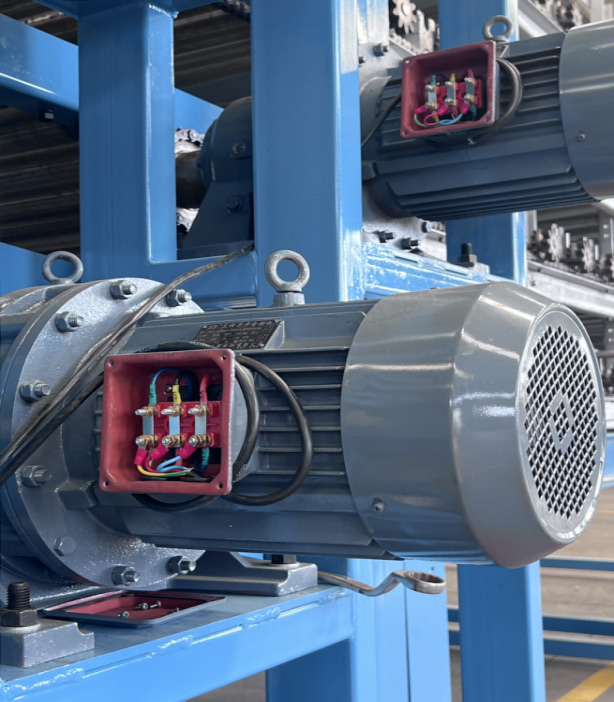

Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood production line

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.Door to door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close