Versatile Technology Veneer Dryer Machinery

Shine Wood Veneer Dryer is an advanced wood drying equipment that is widely used in the wood processing industry.

Adopting an intelligent control system, it can automatically adjust the drying parameters, improve the drying efficiency, and

shorten the drying time. It adopts the latest energy-saving technology and environmentally friendly materials to reduce

energy consumption while minimizing pollution to the environment.

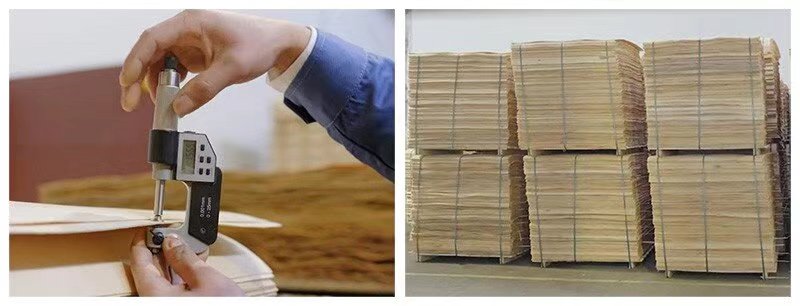

Product Details

Versatile Technology veneer Dryer Machinery

Automatic Roller Dryer is available in different models as per the production requirement by addition & deduction of different sections or decks. The wood high-quality dryer machinery adopts several high-tech and advanced electronic control technologies, so it has the characteristics of high efficiency, energy saving, and good dry quality. Shine wood Veneer Dryer is widely valued for the lowest operation cost, high drying capacity, and energy-efficient as well as high-quality veneer output. It is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad.

Advantages of Versatile Technology Veneer Dryer Machinery

Equipment size: According to different production needs, provide a variety of models and specifications of the dryer, and the user can choose the equipment suitable for their production scale.

Power: The wood veneer dryer adopts a high-efficiency energy-saving heater, the power ranges from tens of kilowatts to hundreds of kilowatts, depending on the model and user needs.

Material: Made of high-strength corrosion-resistant materials to extend the service life of the equipment and ensure the normal operation of the equipment in high-temperature and high-humidity environments.

Drying capacity: The drying capacity of each batch ranges from hundreds to thousands of veneers, which is customized according to the equipment model and user requirements.

Drying cycle**: Depending on the type of wood, thickness, and initial moisture content, the drying cycle generally ranges from a few hours to tens of hours.

Application areas: Widely used in furniture manufacturing, flooring production, construction wood processing, and other fields.

After-sales service: provide professional after-sales service team, equipment installation and commissioning, operation training, technical support, and regular maintenance services.

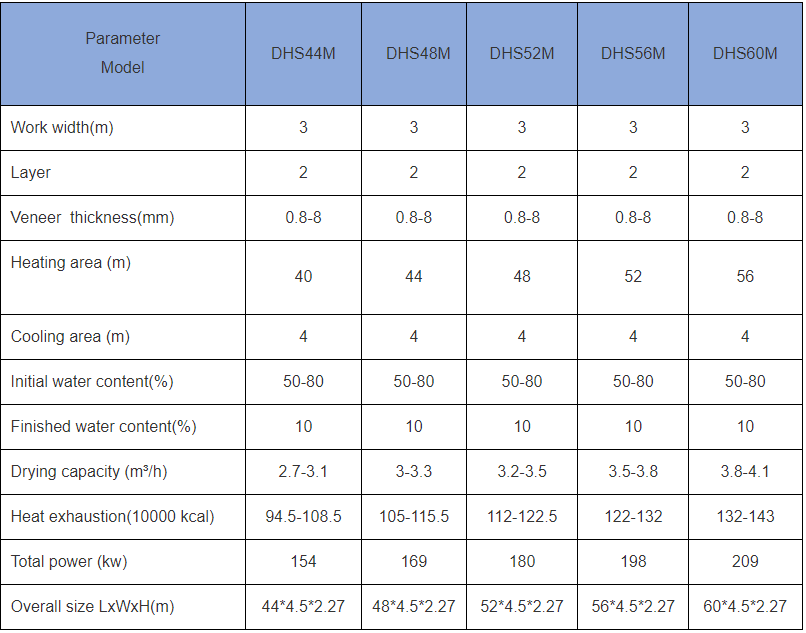

Product Parameters of Versatile Technology Veneer Dryer Machinery

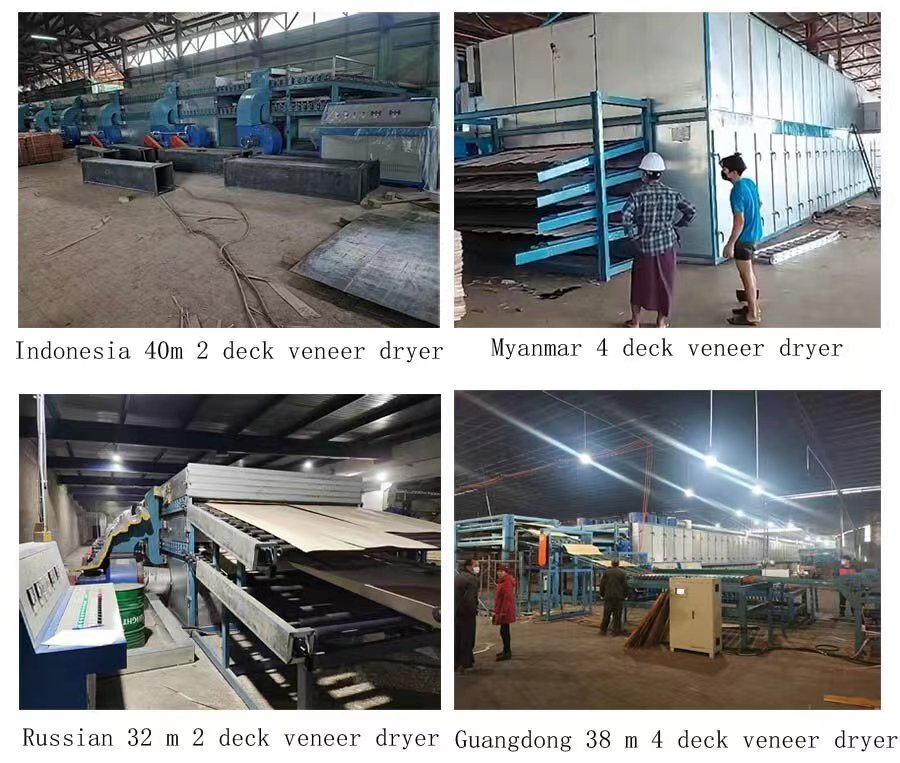

Customer Case

The factory

Shine Machinery is a large-scale manufacturer specializing in R&D of wood veneer dryers and veneer sheet peeling equipment. With decades of growth, Shine Machinery has continuously improved its equipment based on customer feedback. From out first dryer in 1999 to today's 4th generation of the eco-friendly veneer production line, we are dedicated to relentless innovation, providing superior solutions.

The Installation

Our engineers went to the customer's factory to guide the installation of the veneer dryer. With the cooperation of the customer, the four-layer veneer dryer was installed in a short time. During this period, we established a deep relationship with the customer and took a group photo. Take a souvenir. The user is very satisfied with our entire service process and drying equipment. We will continue to purchase our high-quality wood veneer dryers when we expand production in the future.

The Shipping Method

Our After-sales Service

Pre-sale services:

1) Provide free consultation on all veneer production.

2) According to the client's special requirement, offering a reasonable plan and free design to help select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas install and debug the equipment.

3) Train the first-line operator.

After-sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchange. Door-to-door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close