Veneer Dryer Line

The biomass type veneer dryer machine is designed to dry veneers for making plywood, such as eucalyptus, birch, oak, and other wood veneers. The veneer dryer machine is the main machine in the plywood industry and is used to remove moisture from the veneer. The heat medium can be thermal oil and steam which can be produced according to the customer's requirement. Waste wood, tree bark, and waste veneer from the veneer peeling machine can be burned in the biomass burner. The biomass veneer dryer can not only solve the key problem of the high fuel cost of veneer drying equipment but also solve the serious problem of wood processing plant waste accumulation.

Product Details

Product Description of Veneer Dryer Line

Our biomass type veneer dryer machine is made to dry core veneers, such as eucalyptus, birch, oak, and other plywood. The veneer dryer machine is the main machine in the plywood-making industry and is used to remove moisture from the veneer. The heat medium can be thermal oil and heat steam which can be produced according to the customer's requirement. The whole machine can be divided into two parts: the heating section and the cooling section. All the instructions can be operated on the switchboard. Specific requirements can be designed according to the customer's requirements. There are different models of roller veneer dryers, and different veneer dryers are produced according to the production requirements of customers.

The new plywood veneer dryer developed and produced by our company, the waste wood, tree bark, and waste veneer produced by rotary cutting veneer can be burned. The veneer drying machine can not only solve the key problem of the high fuel cost of veneer drying equipment but also solve the serious problem of wood processing plant waste accumulation. Using our veneer dryer machine can greatly reduce the heating equipment combustion cost. The plywood-veneer drying machine must be used together with the sawdust machine, sawdust size can not be greater than 5 cm.

Biomass Burner

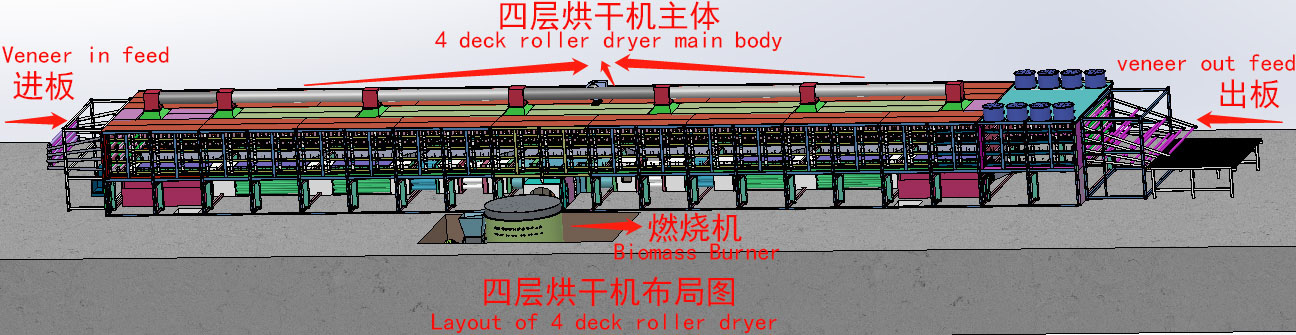

layout of 4 deck roller veneer dryer

Advantages of 4deck Veneer Dryer Line

1. The biomass burner, a patented product independently developed by our company, can directly use crushed wood waste as fuel to provide a heat source for the dryer, which is energy-saving and environmentally friendly, and greatly reduces the drying cost.

2. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste. It has obtained the national invention patent.

3. The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

4. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output.

5. After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

6. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

7. We have a professional R&D team that can design different models according to customers' special requirements.

8. The perfect after-sale service team can supply 24 hours online service.

9. The bearings installed for the three-deck roller dryer are maintenance-free, and high temperature 500℃ resistance and low temperature minus 20℃ resistance, no need for lubricating. Even the bearing sleeve is free of maintenance, with no need for lubricating.

10. Jet box or air tubes in saw tooth thread design prevents veneer jamming.

viedo in customer scene

veneer dryer video of Myanmar customer factory

Product Parameters

Parameter Model |

DHS20M

| DHS22M | DHS24M | DHS26M | DHS28M | DHS30M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 | 4 | 4 |

Veneer thickness(mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Heating area (m)

| 16 | 18 | 20 | 22 | 24 | 26 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | About 3 | About 3.3 | About 3.6 | About 4 | About 4.4 | About 4.8 |

Heat exhaustion(10000 kcal/h) | About 105 | About115 | About126 | About140 | About 154 | About168 |

Total power (kw) about | 105 | 110 | 115 | 120 | 125 | 130 |

Overall size LxW(m) | 31*5.5 | 33*5.5 | 35*5.5 | 37*5.5 | 39*5.5 | 41.*5.5 |

Customer Case

Customers from Malaysia Visit

Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close