Moisture-Resistent Veneer Dryer Production

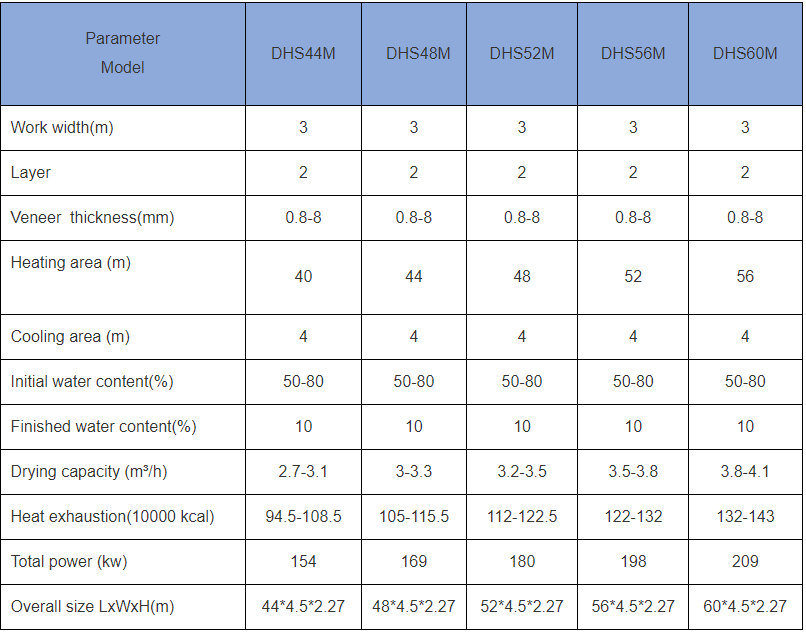

Moisture-Resistent Veneer Dryer Production is a professional drying equipment for veneer and other materials with complete specifications, stable performance and flexible operation. Moisture-Resistent Veneer Dryer Production adopts advanced roller design, driving the upper and lower rollers to run relative to each other by chain, and utilizing hot air and other drying media to dry veneer efficiently.This equipment is widely used in veneer factories, furniture factories, plywood factories and other fields, and is one of the important equipments in wood processing industry

Product Details

Moisture-Resistent Veneer Dryer Production

Shine veneer dryer can provide plywood manufacturing with moisture-resistent wood veneer after drying, which is the key equipment in plywood production line. Shine veneer dryer is a representative of high quality products, providing dry and flat veneer for various decorative finishes. The machine and key components are made of high quality materials and advanced manufacturing technology. It can also saving energy, adopting advanced heating technology and energy-saving design, compared with the traditional dryer can significantly reduce the unit energy consumption.

Advantages of Moisture-Resistent Veneer Dryer Production

Accurate temperature and humidity control system: The temperature and humidity conditions required in the drying process can be accurately set and maintained to ensure the stability and consistency of veneer drying quality.

Good drying uniformity: Whether it is the center or the edge of the veneer, it can ensure the uniformity of heat and moisture distribution, which makes the quality of veneer after drying uniform.

Better environmental performance: For example, the exhaust gas generated by the combustion of the hot air furnace after scientific treatment, in line with environmental emission requirements.

Convenient maintenance: Reasonable structural design makes daily maintenance convenient and quick, reducing equipment downtime maintenance time.

Adapt to different production scale: According to the customer's actual production demand, customized different size and capacity of the dryer.

Good flatness maintenance: In the drying process can minimize the veneer warping, deformation and other problems, to ensure that the veneer drying still maintain a good flatness.

We have a professional R&D team which can design different models according to customer's special requirement.

The perfect after-sale service team can supply 24 hours online service.

Applications

Plywood Factory: As one of the important pieces of equipment for plywood production, the Shine dryer can dry the veneer efficiently and evenly to provide high-quality raw material for subsequent plywood production.

Building Formwork: During the production of building formwork, wood needs to be dried to improve its stability and durability. Shine dryers can meet this need and provide strong support for the production of building templates.

Furniture Manufacturing: Furniture manufacturing often uses a variety of panels as raw materials. Shine dryers can ensure the drying quality of the boards and improve the overall quality of the furniture.

Other Wood Processing Industries: Wood processing industries such as flooring, wooden doors, wooden lines, etc. also need to dry the wood. With its advantages of labor cost, environmental protection, and energy saving, the Shine dryer also has a wide range of application prospects in these fields.

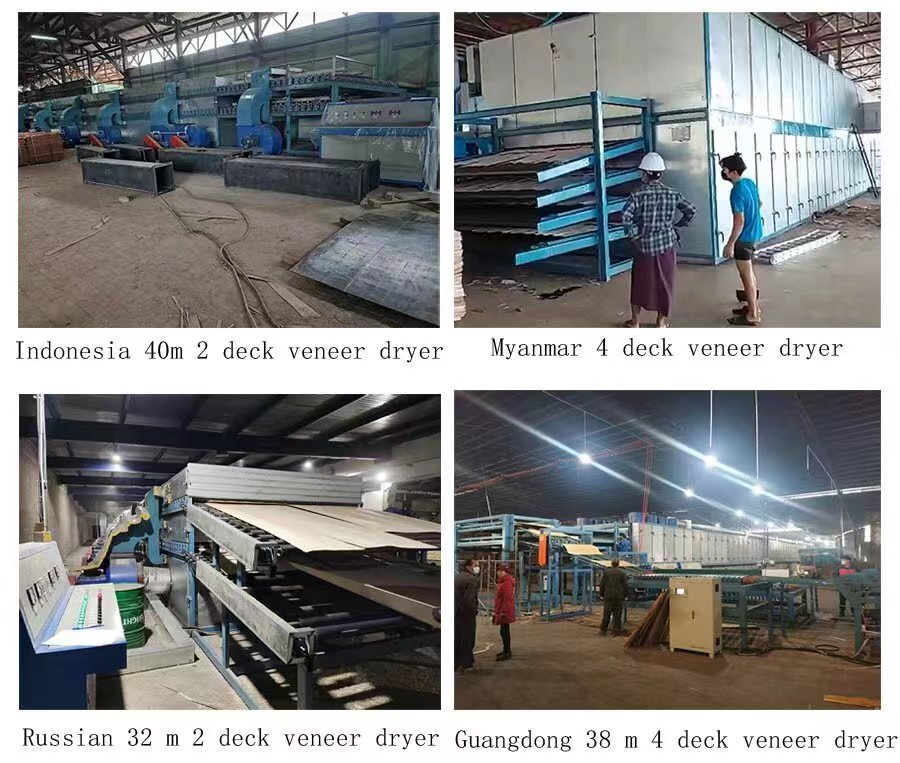

Customer Case and Exhibition

Packaging & Shipping

Company Strength

In the pursuit of high efficiency, environmental protection, and quality in the wood processing industry, as veneer dryer manufacture, the Shine has become a bright star in the industry with its excellent performance, advanced technology,

and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life.

Therefore, Shine has elaborated a series of high-efficiency veneer dryer, aiming to bring an unprecedented drying experience for global wood processing enterprises.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close