Adopting Newly Technology Dryer Machinery

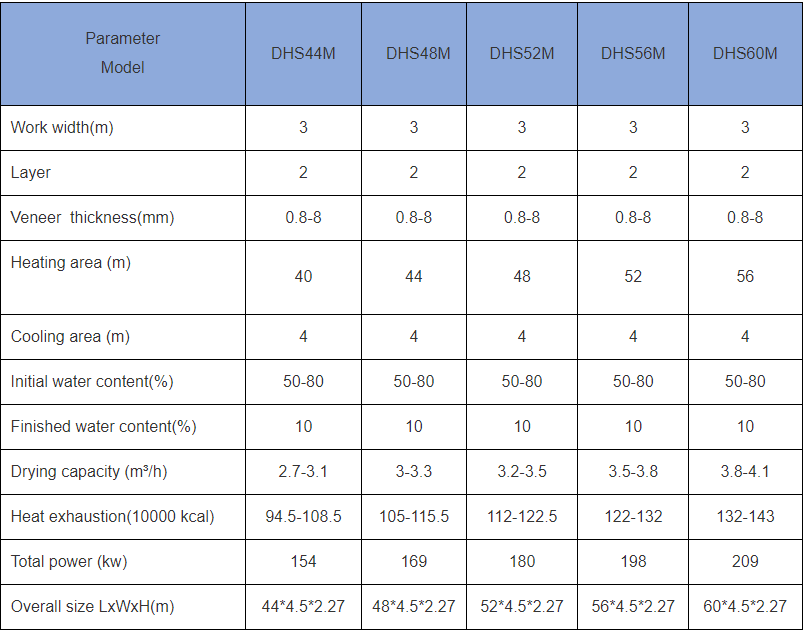

As veneer dyrer manufacture, Shine has precise temperature and humidity control system in intelligent control, which is able to detect and alarm malfunctions and has a high degree of automatic operation. Drying performance has a funny drying efficiency, this machine can produce high-quality products, veneer can maintain good flatness.Shine veneer dryer is able to make efficient use of energy and has better environmental performance. The model of the dryer can be customized according to the demand of veneer with different material thickness.

Product Details

Adopting Newly Technology Dryer Machinery

Shine veneer dryer can provide plywood manufacturing with high quality veneer after drying, which is the key equipment in plywood production line. Shine veneer dryer is a representative of high quality products, providing dry and flat veneer for various decorative finishes. The machine and key components are made of high quality materials and advanced manufacturing technology. It can also saving energy, adopting advanced heating technology and energy-saving design, compared with the traditional dryer can significantly reduce the unit energy consumption.

Advantages of Newly Technology Dryer Machinery

1. Accurate temperature and humidity control system: The temperature and humidity conditions required in the drying process can be accurately set and maintained to ensure the stability and consistency of veneer drying quality.

2. Good drying uniformity: Whether it is the center or the edge of the veneer, it can ensure the uniformity of heat and moisture distribution, which makes the quality of veneer after drying uniform.

3. Better environmental performance: For example, the exhaust gas generated by the combustion of the hot air furnace after scientific treatment, in line with environmental emission requirements.

4. Convenient maintenance: Reasonable structural design makes daily maintenance convenient and quick, reducing equipment downtime maintenance time.

5. Adapt to different production scale: According to the customer's actual production demand, customized different size and capacity of the dryer.

6. Good flatness maintenance: In the drying process can minimize the veneer warping, deformation and other problems, to ensure that the veneer drying still maintain a good flatness.

7. We have a professional R&D team which can design different models according to customer’s special requirement.

8. The perfect after-sale service team can supply 24 hours online service.

Customer Case

Exhibitions and Customer Visits

Our After-Sales Service

Pre-sale services:

1) Provide the free consultation of all Adopting Newly Technology Dryer Machinery.

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close