Customized Natural Wood Veneer Dryer

Customized veneer dryer adopts an automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thicknesses and moisture content to achieve an ideal drying effect.

Product Details

Customized Natural Wood Veneer Dryer

Wood veneer dryers can supply high efficiency with the lowest drying cost. Our veneer drying machine has the advantages of high productivity, energy efficiency, and perfect drying effect. The 2-deck veneer dryer is a high-quality product, equipped with an automatic feeder device that can feed the veneer to the dryer and save labor costs mostly. The natural wood veneer after drying has uniform moisture content and it is flat without buckle or end waviness. Less maintenance is required for the Shine veneer dryer machine and no veneer jamming leads to less downtime. Shine biomass veneer dryer machines can reach users' special requirements and achieve the ideal drying effect.

Advantages

Energy saving and environmental protection: Shine customized veneer dryer adopts a self-developed biomass special burner, which can use black veneer, white veneer, saw head, and other waste wood produced by veneer rotary cutting as fuel, realizing the local material, turning waste into treasure, and greatly reducing the energy cost in the drying process. This combustion method is not only environmentally friendly but also significantly saves fuel costs, compared with steam or heat-conducting oil furnace dryers, drying costs are greatly reduced.

High-efficiency automation: The dryer is equipped with automatic board feeding and splitting system as well as automatic board collecting system, which reduces the need for manual operation, and only 1-2 people are required to be on duty at both ends respectively, which solves the problem of a large number of manual board feeders and high labor intensity. At the same time, it adopts a full-automatic control and frequency conversion control system, which can automatically adjust the transmission speed and temperature according to different veneer thickness and moisture content to achieve an ideal drying effect, and can accurately control the moisture content.

Advanced heat exchanger system: Shine customized veneer dryer adopts a heat exchanger system with a step-by-step heat exchanger, and the heat exchanger of each section has different specifications, so the hot air can be evenly distributed to the veneer, which ensures the uniformity of veneer drying. This design fully improves the utilization rate of energy and saves unnecessary energy waste.

Good drying effect: The temperature inside the oven is 40-60 degrees Celsius higher than that of the traditional dryer (steam, heat-conducting oil), which greatly shortens the total drying time of the veneer and improves the drying output. After drying, the natural wood veneer has even moisture content, flat, has no folds, no cracks, has good surface gluing condition, high yield, and is not easy to deform.

Durable and convenient maintenance: the dryer adopts high-temperature resistant and low-temperature resistant bearings, which are free of oil and maintenance for life, reducing the maintenance cost. Meanwhile, the dryer is designed for easy daily operation and maintenance.

Applications

Plywood Factory: As one of the important pieces of equipment for plywood production, the Shine dryer can dry the veneer efficiently and evenly to provide high-quality raw material for subsequent plywood production.

Building Formwork: During the production of building formwork, wood needs to be dried to improve its stability and durability. Shine dryers can meet this need and provide strong support for the production of building templates.

Furniture Manufacturing: Furniture manufacturing often uses a variety of panels as raw materials. ShengHui dryers can ensure the drying quality of the boards and improve the overall quality of the furniture.

Other Wood Processing Industries: Wood processing industries such as flooring, wooden doors, wooden lines, etc. also need to dry the wood. With its advantages of high efficiency, environmental protection, and energy saving, the Shine dryer also has a wide range of application prospects in these fields.

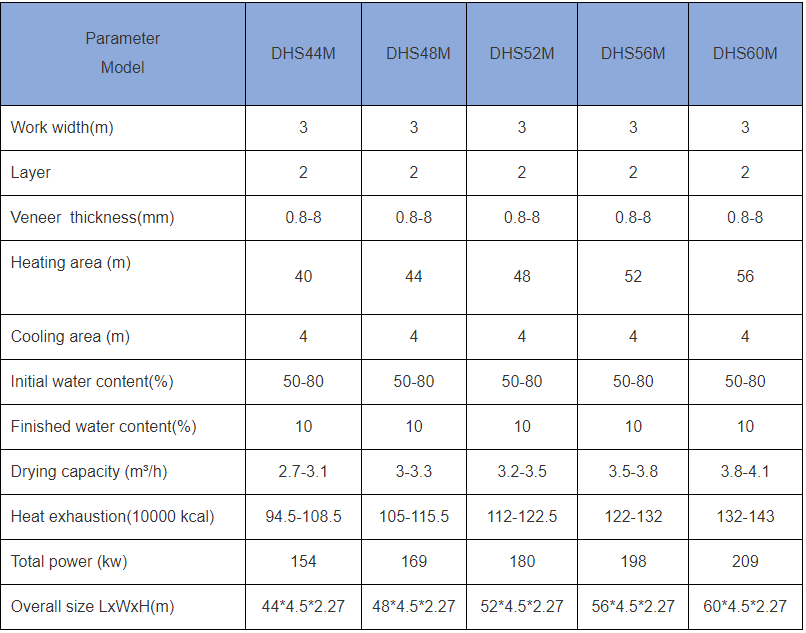

Parameters of the Machine

Customer Case

Setting Machine

Shipping and Packaging

Our Service

Pre-sale services:

1) Provide free consultation for all Customized Natural Wood Veneer Dryer

2) According to the client's special requirement, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas install and debug the equipment

3) Train the first-line operator.

After-sale services:

1) 24-hour online service

2) Provide the video with install and debug the equipment

3) Provide technical exchanging

4) Door-to-door service is possible

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close