Veneer Roller Dryer Machinery for Plywood Production

Product Advatages

1. Low Carbon: SHINE Veneer Dryer Machinery adopts the water dust removal system to make sure no smoke and no dust during the drying process.It is eco-friendly.

2. Low Power Consumption: SHINE core veneer dryer or face veneer dryer machinery apply the axial fan and electric automatica control system which can control the feeding speed and the veneer transmission speed and the temperature to save the unnecessary power loss.

3. Low Fuel Cost:SHINE automstic veneer drying machine adopts biomass burner,which can burn the wet wood and all kinds of wast wood, save the process of removing the waste wood, save the money.

4. High Drying Effect:SHINE tunnel veneer dryer machinery is equipped with several kinds of systems, such as transmission system, automatic system,automatic electric controlsystem,insulation system and air circulation system, dusr removal system and so on. To ensure the flat and soomth veneer after drying.

5. Easy To Installation: SHINE core veneer dryer , face veneer dryer and vertical veneer dryer mchinery, every parts of the machine is could be reoving and installation. Easy to move when you need to move your factory.

6. Best After-Service:We have profeesional technician and they will follw the shipping team to your factory make sure your worker could familiar with the operating of the machine.

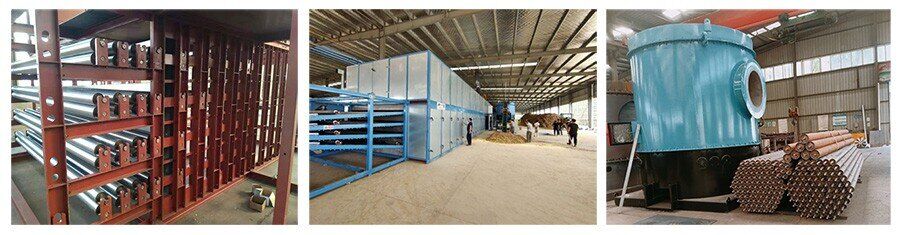

Product Details

SHINE automatic veneer drying machineis a specialized veneer dryer machine manufacturer. SHINE veneer dryer machinery mahciner has roller face veneer dryer and core veneer dryer, vertical veneer dryer. The roller veneer dryer machine is suitable for the veneer producing which has large quantity and good effect and the country where has strict environmental standards. The veeertical veneer dryer is suitable for the veneer producing with small producing and low grade, such as construction template procuing and back board of plywood and so on.

SHINE tunnel veneer dryer machinery has a professional team, they can guid the professional installation. We are never stop in the way of techinic, we always up grade and keep going. To make sure the best machine service for our customer, we dedicated to research the most effcet and low cost machine for our customer. Never stop, never give up!

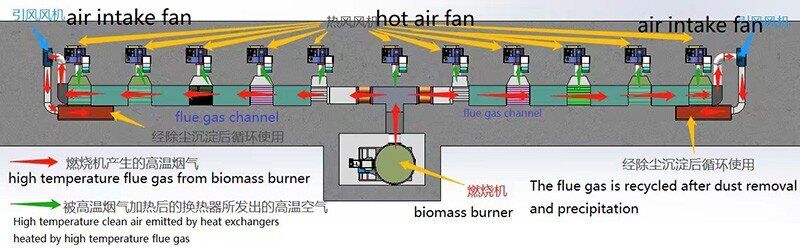

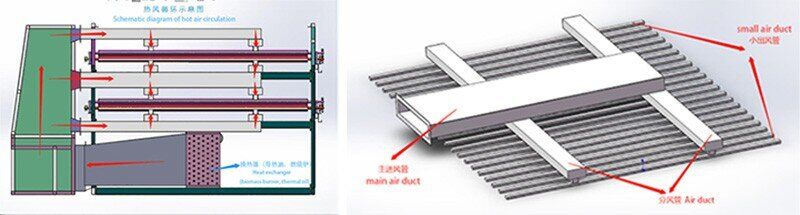

Principle

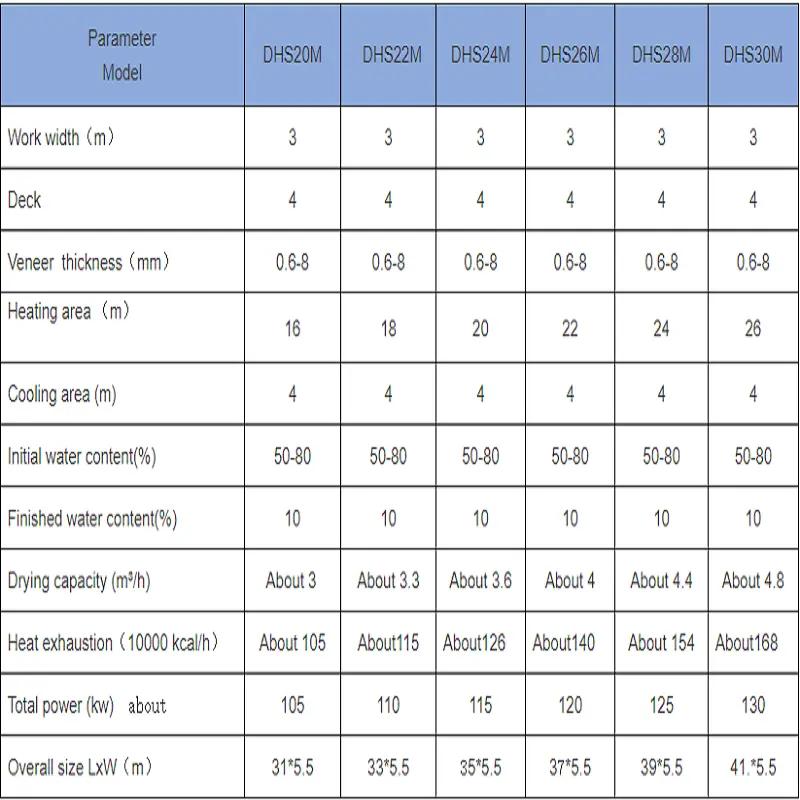

Parametric

Customers

Packing

Installation

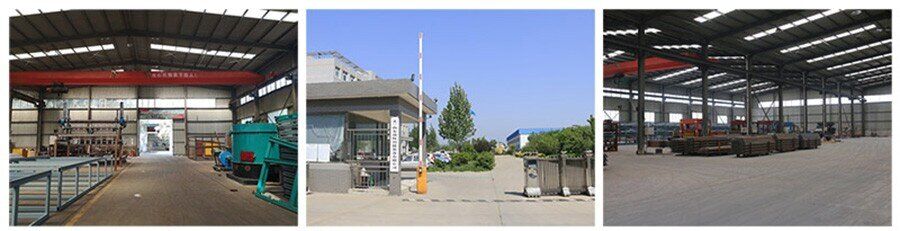

Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood production line

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.Door to door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close