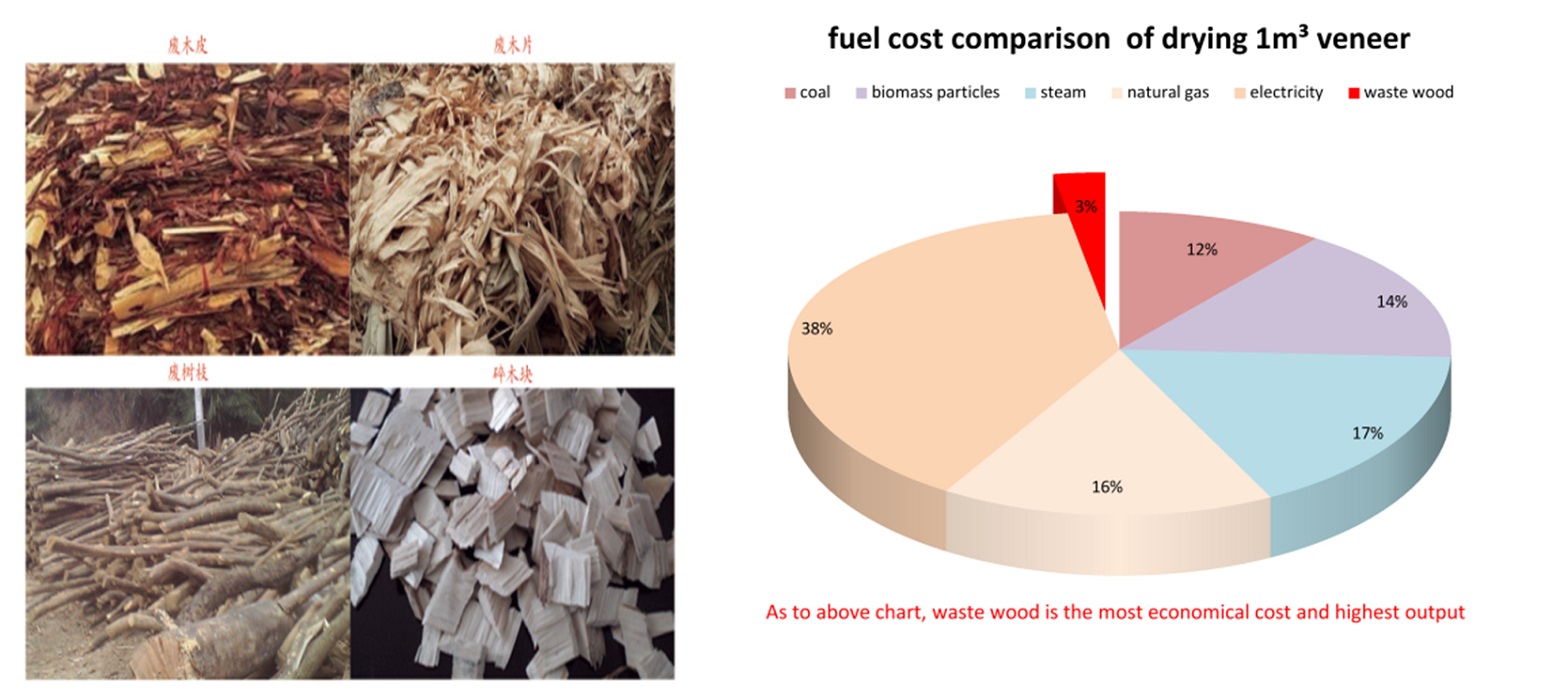

Low Cost Biomass Burner Veneer Dryer

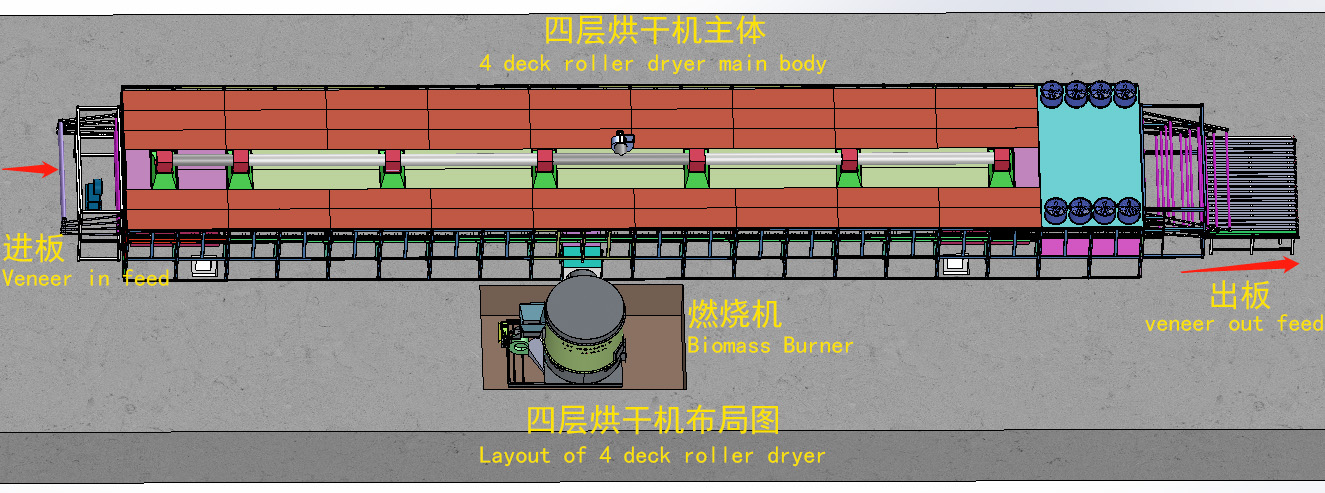

Shine veneer dryer adopts automatic electric control and frequency conversion system,which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect.Equipped with automatic veneer feeder and automatic collection system,which not only improves the drying efficiency but also saves labor cost mostly.

Price

$170,000.00

Product Details

Low Cost Biomass Burner Veneer Dryer

wood veneer dryer machine adopts a number of high-tech and advanced electronic control technology,so it has the characteristics of high efficiency, energy saving and good dry quality.Veneer Drying machine is suitable for peeling core of drying. In order to achieve the best drying efficiency of the injector roller veneer dryer, the machine's shell is insulated by a shell thickness of 75 mm-100 mm,so as to achieve the heat and no air loss within the machine.We also can do other type veneer dryer such as electricity veneer dryer,coal veneer dryer,face veneer dryer and biomass veneer dryer.

Advantages of Veneer drying machine

1.The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

2.The veneer after drying is free of splits and the surface is in good condition for gluing.

3.Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

4.Shine veneer dryer is equipped with automatic control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are international famous brands.

5.Shine veneer dryer adopts frequency conversion, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve an ideal drying effect.

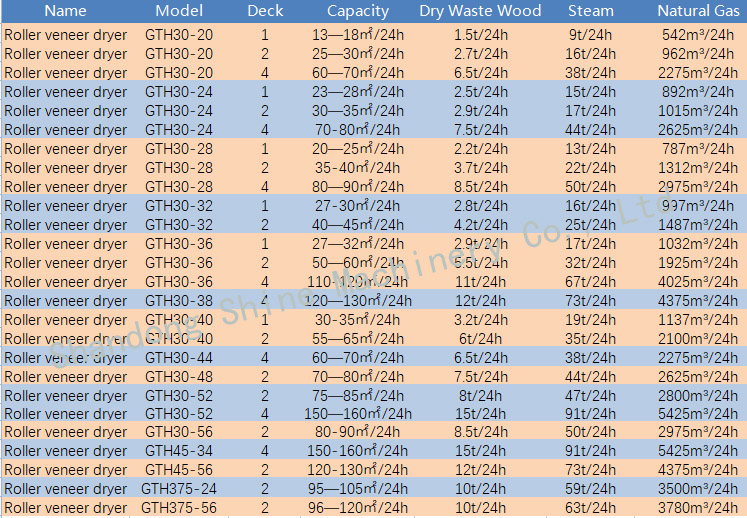

Product Parameters

Parameter Model |

DHS20M

| DHS22M | DHS24M | DHS26M | DHS28M | DHS30M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 | 4 | 4 |

Veneer thickness(mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Heating area (m)

| 16 | 18 | 20 | 22 | 24 | 26 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | About 3 | About 3.3 | About 3.6 | About 4 | About 4.4 | About 4.8 |

Heat exhaustion(10000 kcal/h) | About 105 | About115 | About126 | About140 | About 154 | About168 |

Total power (kw) about | 105 | 110 | 115 | 120 | 125 | 130 |

Overall size LxW(m) | 31*5.5 | 33*5.5 | 35*5.5 | 37*5.5 | 39*5.5 | 41.*5.5 |

The Customer Evaluation

Exhibition

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close