Automatic Veneer Drying Machine

Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. The composite cost is only about $6-12/cubic meter, which can improve customers profit space greatly. We have 10 standardized workshops, covering an area of 70,000 square meters and 150 sets of various machin Dryer es including 6 production lines of machining, heat treatment, punching, welding, assembling and painting.

Product Details

Product Description of Automatic Veneer Drying Machine

Shine roller veneer dryer is of high quality and efficiency and is the best choice for plywood veneer drying.Roller type wood veneer dryer can keep the veneer smooth and has uniform moisture content after drying. The output of veneer with the thickness of 0.5-5mm through veneer drying machine. Waste wood and other waste bark can be used as the fuels for thiccoreveneer drying line, saving the cost significantly. The composite cost is about only USD 6-12/cubic meter. Our biomass burner of veneer dryer machine can use waste wood as fuel ,which is environmental,saving energy,reduce cost and also there is no any smoke.

Biomass Burner

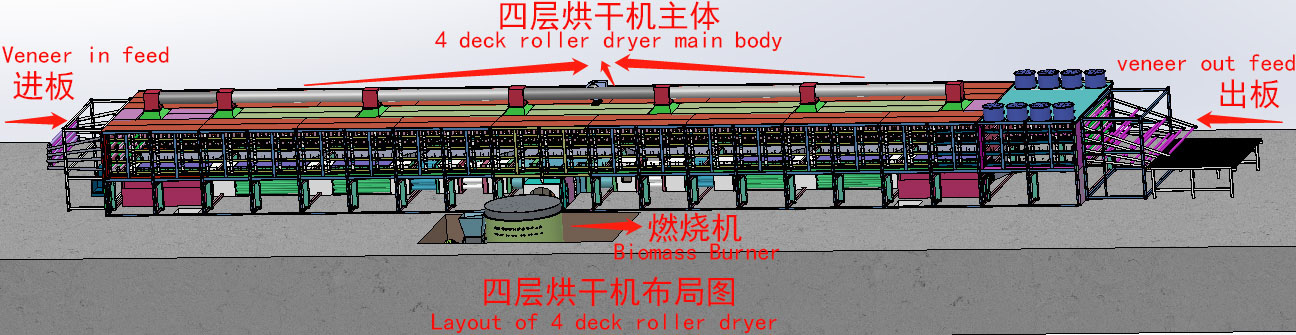

layout of 4 deck roller veneer dryer

Advantages of roller veneer dryer

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

4.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

5. The fuel source can be the waste wood after peeling or the tree bark ,which can reduce the fuel cost greatly for the user.

viedo in customer scene

veneer dryer video of customer factory

Product Parameters of Automatic Veneer Drying Machine

Parameter Model |

DHS20M

| DHS22M | DHS24M | DHS26M | DHS28M | DHS30M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 | 4 | 4 |

Veneer thickness(mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Heating area (m)

| 16 | 18 | 20 | 22 | 24 | 26 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | About 3 | About 3.3 | About 3.6 | About 4 | About 4.4 | About 4.8 |

Heat exhaustion(10000 kcal/h) | About 105 | About115 | About126 | About140 | About 154 | About168 |

Total power (kw) about | 105 | 110 | 115 | 120 | 125 | 130 |

Overall size LxW(m) | 31*5.5 | 33*5.5 | 35*5.5 | 37*5.5 | 39*5.5 | 41.*5.5 |

Customer Case

Customers from Malaysia Visit

Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close