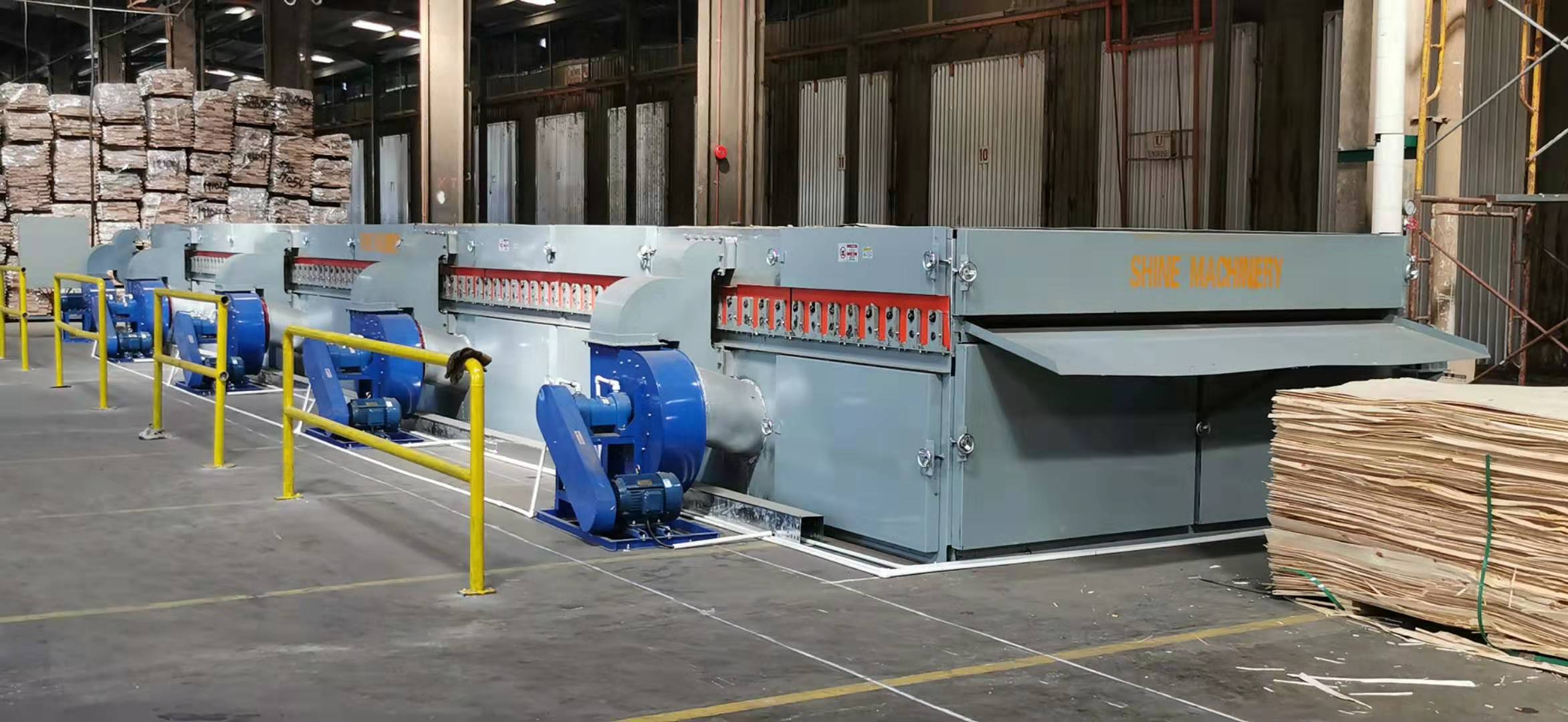

1-deck roller veneer drying machine

1-deck Roller veneer Dryer compared with Vertical Veneer Dryer, the former can output A-class veneer with high quality and the face of veneer can be more flatness, because the dryer has a higher temperature inside that provided by the biomass burner. Also the rollers and gears of the dryer could be more convenient for daily maintain.

Product Details

Product Detail Picture

Product technical parameter of 1-deck Roller Dryer

Parameter Model | DHS36m | DHS38m | DHS40m |

Heating area(m) | 32 | 36 | 40 |

Working Width(m) | 3 | 3 | 3 |

Deck | 1 | 1 | 1 |

Veneer thickness (mm) | 0.6-8 | 0.6-8 | 0.6-8 |

Veneer water moisture | Fresh Veneer to about 5% | Fresh Veneer to about 5% | Fresh Veneer to about 5% |

Drying capacity (m³/day) | About 1.34 cbm | About 1.5 cbm | About 1.67 cbm |

Total Power | 57KW | 62.5KW | 68KW |

Actual electricity consumption | About 40kwh per hour | About 43kwh per hour | About 47kwh per hour |

Overall Dimension(L*W) | 40m×5m | 42m×5m | 44m×5m |

Company Profile

Shandong Shine Machinery Co., Ltd is established in 1999 and we are a large scaled enterprise and specialized in R&D of machinery for veneer production, products are including wood veneer peeling line and veneer drying line. Shine has 10 standard workshops, covering an area of 70,000 square meters and 150 sets of productions, including 6 detailed production lines of machining, heat treatment, punching, welding, assembling and painting. We have a professional R&D team(more than 50 persons for the design) and experienced after-sale service team to supply one-stop solution & customization. Our machines, especially for veneer dryers are enjoying worldwide reputation, have won the CE certificates and been exported to more than 20countries such as Latvia, Thailand, Laos, Malaysia, Cambodia, Myanmar, Brazil, South Africa, South America, Ethiopia, Zimbabwe, The Republic of Congo and etc.

Our Service

We have a professional R&D team that can design different models according to customer’s special requirement.

Also, a perfect after-sale service system, which can supply 24h online service; remote operation is available on request, regular customer visits, sufficient spare parts supply in time.

With decades of growth, SHINE Machinery has continuously improved our equipment based on customer feedback. From our 1999 debut dryer to today's fourth-gen eco-friendly veneer production line, we're dedicated to relentless innovation, providing superior solutions.

Products packaging

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close