Tunnel veneer dryer for smaller capacity output customer

Faster drying times: Tunnel wood veneer dryers are designed to dry wood veneers more quickly than other drying methods, increasing production efficiency and reducing lead times.

Space-saving design: Tunnel dryers have a smaller footprint compared to horizontal dryers, making them ideal for facilities with limited space and allowing for more efficient use of floor space.

Product Details

Product advantages and feature

Consistent drying: Tunnel dryers provide uniform drying across all layers of wood veneers, ensuring consistent moisture content and quality throughout the drying process.Tunnel dryers are often equipped with energy-efficient heating systems and air circulation mechanisms, helping to reduce energy consumption and operating costs.Many wood veneer tunnel dryers are equipped with automation features that allow for precise control of drying parameters, reducing the need for manual intervention and ensuring consistent drying results.Tunnel dryers are typically designed to make efficient use of space in the production facility, allowing for optimal layout and workflow optimization.

Main technical and parameter

Model No | Vertical Veneer Dryer(FBH30-10) |

Veneer Water Moisture(%) | Fresh veneer to about 8% |

Veneer size | 1270mmx640mmx1.7mm |

Drying Capacity (m³/H) | 1.5 |

Hot Air Blower(KW) | 6 (600Wx10pcs) |

Traction Motor(KW) | 1.5 |

Air Intake Fan(KW) | 3 |

Built-in Burner(KW) | 1.5 |

Total Power (KW) | 12 |

Actual Fuel Consumption(KG/H) | 150 |

Space Covered About | 10mX3mX4m |

Working Labors | 2-3 |

Certification

CustomerVisiting

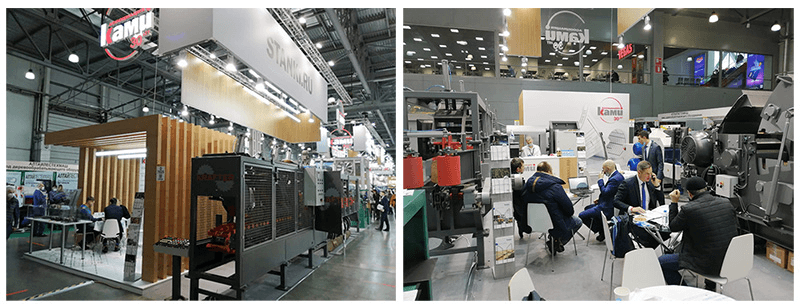

Exhibition

Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood production line

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.Door to door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close