Veneer Dryer With Feeder

Roller veneer dryer machine has an advanced heat exchanging structure with features of high heat exchange efficiency and low heat loss. The core veneer dryer can be heated by a steam boiler, thermal oil heater, or biomass burner which can save the fuel cost the most. Shine veneer dryer adopts automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect. Equipped with automatic veneer feeder and automatic collection system, which not only improves the drying efficiency but also saves labor cost mostly.

Product Details

Product Description of Veneer Dryer

veneer roller dryer is a new generation wood veneer drying machine. By adopting latest international pressure contact veneer drying technology, Shine roller veneer dryer has the advantage of high veneer drying capacity, lowest operate cost, energy efficiency and high quality dried veneer. The veneer after drying has the uniform moisture content, flat, no waviness and shrinkage is kept to a minimum. The surface is in good condition for gluing for plywood process.

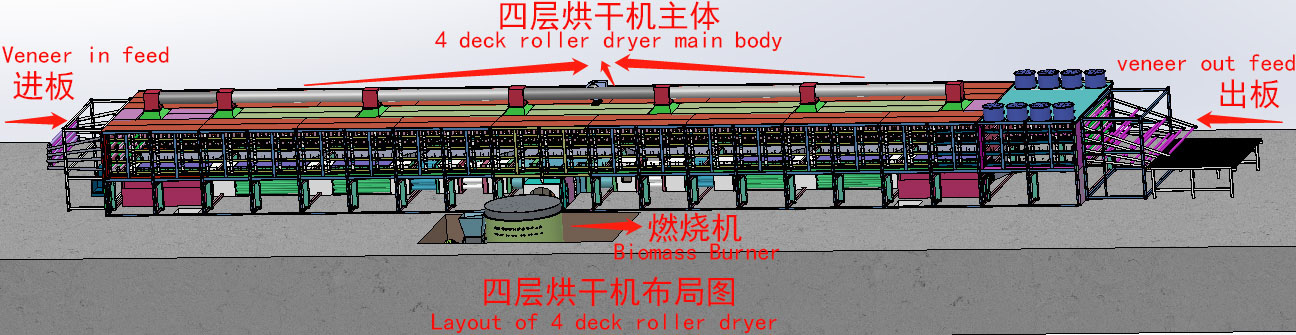

The veneer dryer is driven by the chain to run the upper and lower rollers, relying on the upper roller to press the veneer to run. Biomass combustion furnace is used to burn wood chips, waste wood and other materials at high temperature. Materials boil and fluidize in the burner to provide heat energy to the veneer dryer.For process the surface veneer and long core veneer, this veneer dryer can avoid the break of the veneer, then can raise the veneer utilization ratio and production output.

4deck veneer drying machine in Myanmar scene

Our patented product——Biomass Burner, which can burn the broken waste wood directly as a fuel to provide a heat source for the roller veneer dryer. It is energy-saving and environmentally friendly, and reduces the drying cost greatly.Compared to steam type or heat conduction oil type veneer dryer, the drying cost is reduced greatly.

layout of 4 deck roller veneer dryer

Features of Veneer Dryer

1. Shine biomass veneer dryer has the features of high veneer drying productivity,energy efficiency, lowest drying veneer cost and perfect veneer drying effect.The composite running cost is only about $12/cubic meter,which can improve customers' profit space greatly.

2. Customized working width of the 4deck veneer dryer is 4500m,the main body of the core veneer roller dryer is 40 meters length,divided into 36 meters drying chamber,and veneer cooling chamber 4 meters length.

3. The working layers, working width, and heating length of the Shine veneer dryers are available to be customized as per customers' specical requirements.

4. Shine Machinery is the only one factory in China who can make not only veneer dryer but also the heat source of the roller dryer, namely, biomass burner.

5. Unlike the steam boiler or thermal oil heater which are traditional heat source installed for the dryer, the biomass burner is the exclusive patented product that can completely burn crushed wood chips, and tree barks directly as the fuel, solving the waste accumulation problem in the veneer and plywood making factories. At the same time, the fuel cost is reduced mostly.

6. Professional R&D team can design different veneer dryer models according to customers' special requirements.

7. Perfect after-sale service system can ease the mind of customer after installation as we supply 24 online services and remote operation. Regular follow up service for old customers, and sufficient spare parts supply in time.

viedo in customer scene

veneer dryer video of Myanmar customer factory

Product Parameters

Parameter Model |

DHS20M

| DHS22M | DHS24M | DHS26M | DHS28M | DHS30M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 | 4 | 4 |

Veneer thickness(mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Heating area (m)

| 16 | 18 | 20 | 22 | 24 | 26 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | About 3 | About 3.3 | About 3.6 | About 4 | About 4.4 | About 4.8 |

Heat exhaustion(10000 kcal/h) | About 105 | About115 | About126 | About140 | About 154 | About168 |

Total power (kw) about | 105 | 110 | 115 | 120 | 125 | 130 |

Overall size LxW(m) | 31*5.5 | 33*5.5 | 35*5.5 | 37*5.5 | 39*5.5 | 41.*5.5 |

Customer Case

Customers from Malaysia Visit

Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close