Conveyor Veneer Dryer Machinery

Shine heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer.The veneer after drying has uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

Price

$90,000.00

Product Details

Conveyor Veneer Dryer Machinery

The veneer dryer is driven by the chain to run the upper and lower rollers, relying on the upper roller to press the veneer to run.Biomass combustion furnace is used to burn wood chips,waste wood and other materials at high temperature.Materials boil and fluidize in the burner to provide heat energy to the veneer dryer.For process the surface veneer and long core veneer,this veneer dryer can avoid the break of the veneer,then can raise the veneer utilization ratio and production output.

Advantages of Veneer Drying Machine

1.The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

2.The veneer after drying is free of splits and the surface is in good condition for gluing.

3.Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

4.Shine veneer dryer is equipped with automatic control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are international famous brands.

5.Shine veneer dryer adopts frequency conversion, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve an ideal drying effect.

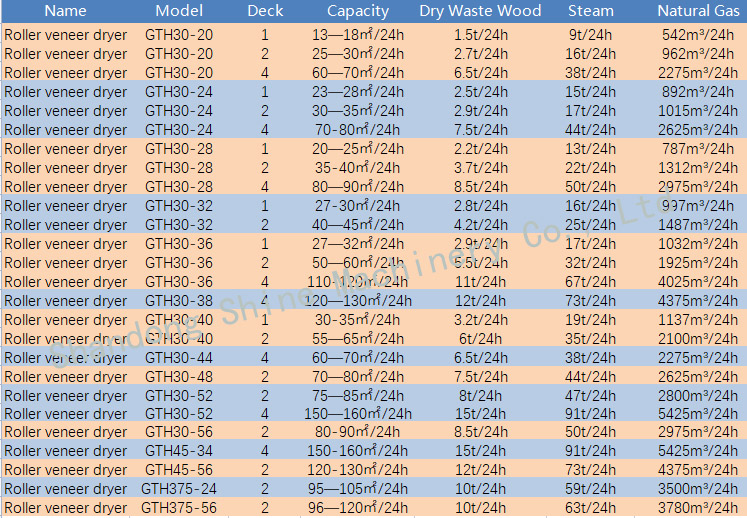

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 48 | 52 | 56 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Total power (kw) | 154 | 169 | 180 | 198 | 209 |

Overall size LxWxH(m) | 44*4.5*2.27 | 48*4.5*2.27 | 52*4.5*2.27 | 56*4.5*2.27 | 60*4.5*2.27 |

Customer Case

The Customer Evaluation

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close