Biomass Vertical Core Veneer Dryer Machine Supplies

The heating system of biomass burner can realize in-situ combustion, and the waste wood, waste bark and waste veneer produced by rotary cutting veneer can be burned. It not only solves the key problem of high fuel cost of vertical core veneer drying equipment, but also solves the problem of serious accumulation of waste materials in wood processing plants.

Product Details

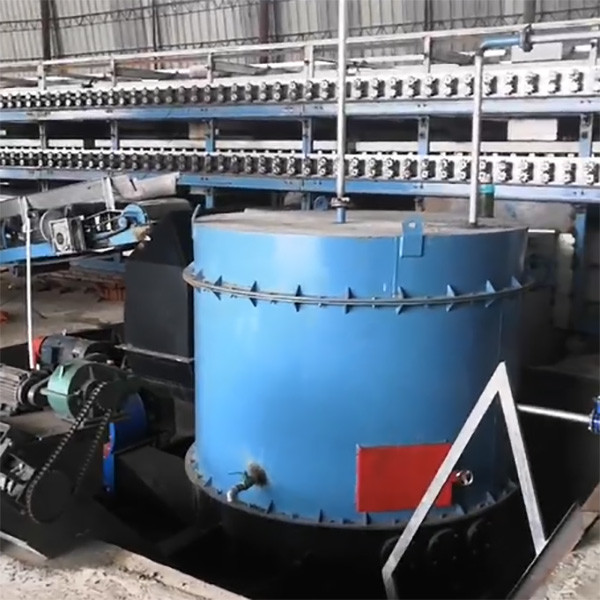

Biomass Vertical Core Veneer Dryer Machine

1、Precise air distribution ratio can ensure stable, full and efficient combustion of fuel.

2、Innovative grate design can achieve the full mixing of fuel and the overall stability of the flame.

3、Water circulation cooling system, to ensure that the burner continues to operate at high temperatures.

4、All parts are easy to disassemble, repair and maintain.

5、Feeding, main wind, air distribution, grate all adopt frequency conversion power to ensure the ratio of fuel, flame, air volume, to ensure the safety and efficiency of combustion.

6. Local materials, energy saving and environmental protection,energy efficient in veneer drying is and reduces energy losses due to energy conversion

The Factory

Packing & Shipping

Customer Cases

Our Service

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close