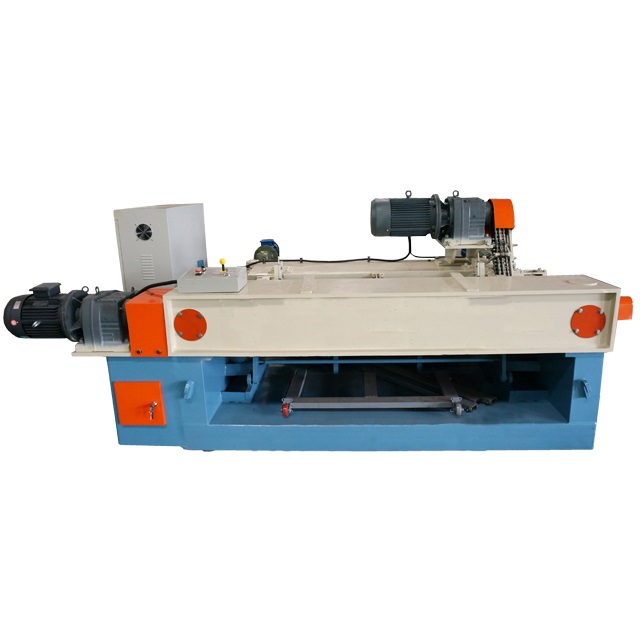

Wood Core Veneer Peeling Machine Lathe For Plywood

High performance CNC system control feeding.The board is smooth, with high productivity.Automatic adjustment of cutting system, skin is much more uniform and smooth. Apply to woods with different diameters.

Price

$12,000.00

Product Details

Wood Core Veneer Peeling Machine Lathe For Plywood

Rotary cutting method has high production efficiency and high wood utilization rate. Spindleless veneer peeling machine is used for making veneer. This veneer peeling machine is designed for the rotary cutting of the logs with different hardness. All the motors adopt full servo motors, the speed of the rotary cutting is stable, the precision of high-speed rotary cutting is guaranteed, and the quality of the veneer is high.

Advantages of 4 Feet veneer peeling machine

1. Double roller drive ensure good stability and high uniformity of peeler.

2.T10 reducer -- low vibration ,smooth and steady transmission ,low noise , high bearing capacity .

3. Hydraulic knife holder saving manpower ,simple operation and automatic.

4. Automatic adjust knife sewing -- double convex rail design structure,more accurate ,faster and more stable than the original

single convex rail adjustment ,and no manul screw adjustment workers ,saving manpower.

Main Parameters for 4 Feet Peeling Machine

log peeling length | 970mm-1270mm |

veneer peeling width range | 660-2600mm |

veneer thickness peeling range | 1.0-4.0mm |

Max. log diameter | 650mm |

min.core veneer after peeling | 38mm |

peeling speed | 48m/min |

Single roller motor | 11kw*2pcs |

Double roller motor | 11kw*2pcs |

feeding motor power | 11kw |

clipper and rubber roller motor | 5.5kw+2.2kw |

Total power | 62.7kw |

Leftover core clapper | pneumatic |

single double roller diamenter and type | 125mm(diamond shape, chromeplate) |

Main reducer model | R87 hardened gear surface |

Total weight | 13000kgs |

Overall dimension | 5800*2300*1500mm |

Company Profile

Shandong Shine Machinery Co., Ltd.is a large-scale enterprise specializing in R&D and production of veneer rotary cutting and veneer dryer equipment. Since its inception, the company has been adhering to the vision of “making first-class corporate contributions, building first-rate enterprise talent, creating first-class corporate brand,implementing modern enterprise management system, using new sales concepts and service systems, and investing 10 million yuan in scientific research each year. It also combine industrial universities to study high-end technology, so that Shine's veneer dryer products are always at the forefront of the industry's technology. Shine roller veneer dryer products are sold to various provinces and cities in the country, and exported to Russia, South Africa, Southeast Asia and many other countries and regions.

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close