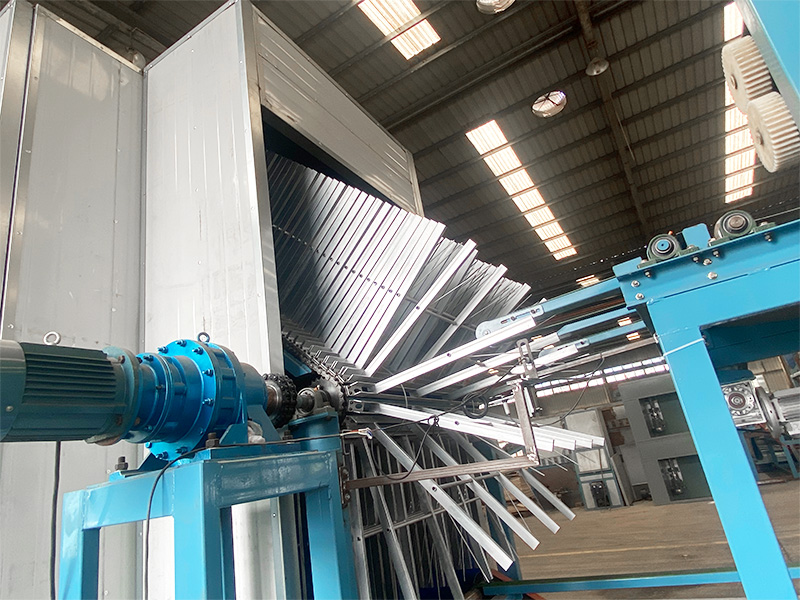

Shine Vertical Veneer Dryer in Myanmar

Small footprint, with a length of less than 20 meters and a width of about 5 meters, small factory buildings can also be used.

The drying cost is low, only 3 workers are needed per shift, and approximately 150 kg of tree stems and 24 kilowatt hours of electricity are consumed per hour. The drying cost per unit is around $10, and even small production can enjoy lower drying costs.

Product Details

Product Introduction of Vertical Veneer Dryer

Recently, our Vertical Veneer Dryer has received positive feedback from customers. It adopts a reciprocating structure, which improves the efficiency of thermal energy utilization and enhances the efficiency of factory space utilization. Low drying cost, high drying efficiency, capable of drying about 1.5 square meters of veneer per hour.

Product Parameters of Shine Vertical Dryer

Model No | vertical veneer dryer(FBH30-10) |

Veneer Water Moisture(%) | Fresh veneer to about 8% |

Drying Capacity (m³/H) | 1.5 |

Hot Air Fan(KW) | 3KW*4 |

Traction Motor(KW) | 5.5KW*1(Frequency Conversion) |

Air Intake Fan(KW) | 7.5KW*1 |

Built-in Blast Furnace(KW) | 1.1KW*1 |

Gas Station Power(KW) | 3KW |

Water Pump Power(KW) | 2.2KW |

Chain Conveying Power(KW) | 1.5KW |

Veneer Conveyor Belt(KW) | 1.5KW(Frequency Conversion) |

Total Power(KW) | 34.3KW |

Actual Fuel Consumption(KG/H) | 150 |

Space Covered About | About 18.5mX5mX4m |

Working Labors | 3 |

Certificate

Transportation

Our Serivce

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory.

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment.

5.Train the first-line operator.

6.Provide the video with Install and debug the equipment.

7.Provide technical exchanging.

8.Door to door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close