Plywood Roller Veneer Jet Dryer

Roller Veneer Dryer is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad. We have a professional R&D team that can design different models according to customer’s special requirement. Shine Veneer Dryer is the most economical dryer available because it consumes much lower power as compare to the any other brand.

Veneer thickness(mm):0.6-0.8

Finished water content(%): 10

Drying capacity (m³/h): 3-4.8

Price

$170,000.00

Product Details

Product Description

The plywood roller veneer jet dryer adopts frequency conversion(The temperature controller is connected to the frequency converter of the traction motor )to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect. Veneer Dryer made by Shine Machinery can be applied for the drying process of top and bottom veneer and thickened core veneer. Featured with perfect drying effect and lowest drying cost, applied with the advantages of the advanced veneer dryers in and abroad, and designed for the purpose of economy, trustiness and high grade, our product guarantees a promotion of yield, an improvement of products, a cut of energy consuming and production cost, as well as satisfactory increasing benefit.

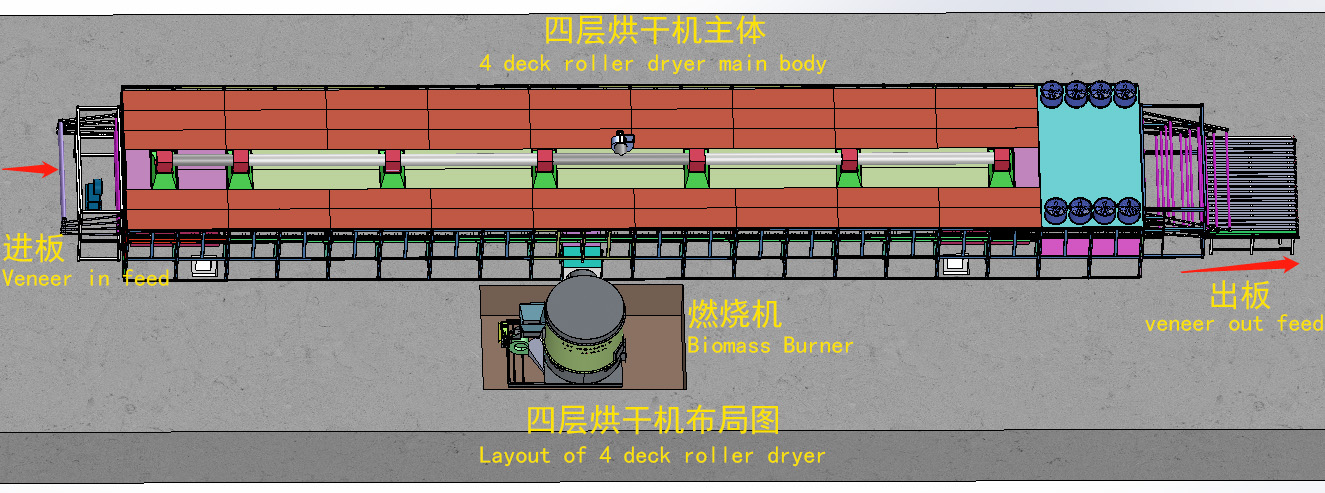

4 deck veneer drying machine

layout of 4 deck roller veneer dryer

Main Features of Roller Veneer Dryer

1.The machine is the main apparatus in plywood industry.

2. It uses to remove moisture from the veneer.

3.The heat medium can be thermo oil and heat steam.

4.The whole machine can be divided into two parts: heating section and cooling section.

5.It includes mesh type, roller type, mesh&roller type, could be customized according to your requirements.

veneer dryer video

Product Parameters

Parameter Model |

DHS20M

| DHS22M | DHS24M | DHS26M | DHS28M | DHS30M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 | 4 | 4 |

Veneer thickness(mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Heating area (m)

| 16 | 18 | 20 | 22 | 24 | 26 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | About 3 | About 3.3 | About 3.6 | About 4 | About 4.4 | About 4.8 |

Heat exhaustion(10000 kcal/h) | About 105 | About115 | About126 | About140 | About 154 | About168 |

Total power (kw) about | 105 | 110 | 115 | 120 | 125 | 130 |

Overall size LxW(m) | 31*5.5 | 33*5.5 | 35*5.5 | 37*5.5 | 39*5.5 | 41.*5.5 |

Customer Case

Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close