Automatic loading 4-deck veneer drying machine

Efficiency. It avoids board problems caused by unskilled manual loading and fatigue, and cooperates with the dryer to dry the veneer more quickly. Save labor costs. Machines can replace labor to the greatest extent. For example, in countries where labor costs are relatively high, fully automatic plate loading machines will be a better choice.

Product Details

Product advantages and feature

1. Increase production. The working upper limit of manual loading is fixed, but the fully automatic loading machine of the roller veneer dryer can set different speeds to match the drying speed to maximize production capacity.

2. High degree of automation. The fully automatic plate loading machine is matched with the roller veneer dryer to meet the high automation needs of customers with large output, improving the drying efficiency of veneers while ensuring drying quality.

Main technology and parameter

Parameter Model | DHS34m | DHS36m | DHS38m | DHS40m |

Heating area(m) | 30 | 32 | 34 | 36 |

Working Width(m) | 3 | 3 | 3 | 3 |

Deck | 4 | 4 | 4 | 4 |

Veneer thickness (mm) | 0.6-8 | 0.6-8 | 0.6-8 | 0.6-8 |

Veneer water moisture | Fresh Veneer to about 5% | Fresh Veneer to about 5% | Fresh Veneer to about 5% | Fresh Veneer to about 5% |

Drying capacity (m³/day) | About 4.4 cbm | About 4.7 cbm | About 4.96 cbm | About 5.25 cbm |

Total Power | 166KW | 174KW | 182KW | 190KW |

Actual electricity consumption | About 116kwh per hour | About 121kwh per hour | About 127kwh per hour | About 133kwh per hour |

Overall Dimension(L*W) | 38m×5m | 40m×5m | 42m×5m | 44m×5m |

Certification

CustomerVisiting

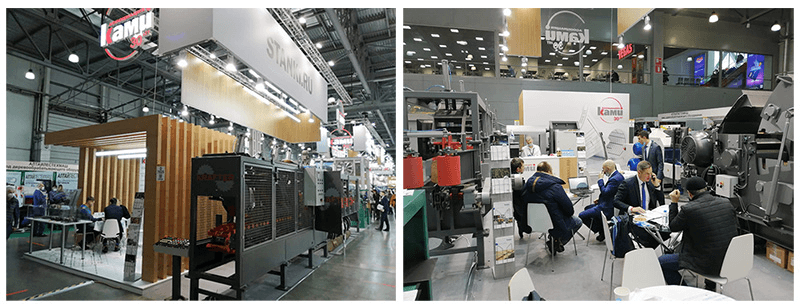

Exhibition

Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood production line

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.Door to door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close