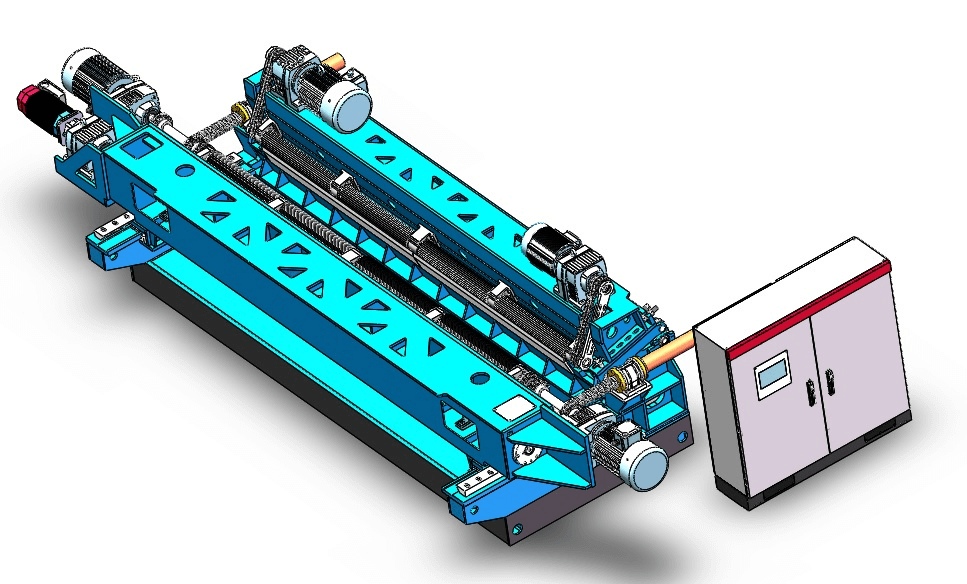

9Feet Wood Peeling Machine with double row rotary cutting

This 9ft wood peeling machine adopts building block installation, fixed knife table, double-row walking structure, thicknened lead screw, oil-immersed light rod, and automatic adjustment of the knife gap. It is more stable when rotary cutting wood and the board output is more uniform.

Product Details

Product advantage

The rotary cutting speed can be adjusted according to customer requirments, and it is simple to operate.

Easy to maintain, small in occupied space, saving labor cost.

Highly automated, durable and energy-saving.

Main technology and parameter of 9ft double row rotary cutting machine

Model | Unit | Parameter |

| mm | 1300-2800mm |

| Wood diameter | mm | Max to 550mm |

| Thickness range | mm | 0.4-3mm |

| Remaining wood core | mm | 32 |

Motor power | KW | 63 |

Double stick diameter | mm | 124 |

Single stick diameter | mm | 100 |

Machine size | mm | 6200mm-2300mm- 1600mm |

Total weights | kg | 9000 |

Company Profile

Shandong Shine Machinery Co., Ltd is established in 1999 and we are a large scaled enterprise and specialized in R&D of machinery for veneer production, products are including wood veneer peeling line and veneer drying line. Shine has 10 standard workshops, covering an area of 70,000 square meters and 150 sets of productions, including 6 detailed production lines of machining, heat treatment, punching, welding, assembling and painting. We have a professional R&D team(more than 50 persons for the design) and experienced after-sale service team to supply one-stop solution & customization. Our machines, especially for veneer dryers are enjoying worldwide reputation, have won the CE certificates and been exported to more than 20countries such as Latvia, Thailand, Laos, Malaysia, Cambodia, Myanmar, Brazil, South Africa, South America, Ethiopia, Zimbabwe, The Republic of Congo and etc.

Our Service

We have a professional R&D team that can design different models according to customer’s special requirement.

Also, a perfect after-sale service system, which can supply 24h online service; remote operation is available on request, regular customer visits, sufficient spare parts supply in time.

With decades of growth, SHINE Machinery has continuously improved our equipment based on customer feedback. From our 1999 debut dryer to today's fourth-gen eco-friendly veneer production line, we're dedicated to relentless innovation, providing superior solutions.

Products packaging

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close