4 Feet wood veneer rotary peeling machine with double row

Veneer peeling consists of block centering, peeling, veneer analyzing, clipping and stacking as well as stack handling processes, all of which have an impact on your production performance.The peeling process determines the profitability of the entire veneermanufacturing chain and the volume of face quality sheets that can be produced. With optimal peeling and clipping you maximizeveneer quality for further processing and your veneer production capacity.

Product Details

Product advantages and features

The cutting speed of Shine wood peeling machine can be adjusted according to customer needs, and simple operation, easy maintenance, small area, manpower saving, high degree of automation, durable and power saving, first-class product quality.This machine adopts building block installation, fixed tool table, double-row walking structure, thickened oil cylinder, hydraulic propulsion, and balance bar. It is more stable when finding round wood, the rotary cutting wood is smoother, and it is more efficient.

Main technical parameter

Max. Processing Length | 1400mm |

Rubber Roller Diameter | 245mm |

Max. Working Thickness | 20mm |

Chromate Treated Roller Diameter | 210mm |

Number of Rubber Rollers | 2 |

Number of Chromate Treated Rollers | 2 |

Motor Power | 3kw, 380V-50Hz 3phase |

Overall Dimension | 2200x1200x1400mm |

Weight | 800kgs |

Certification

CustomerVisiting

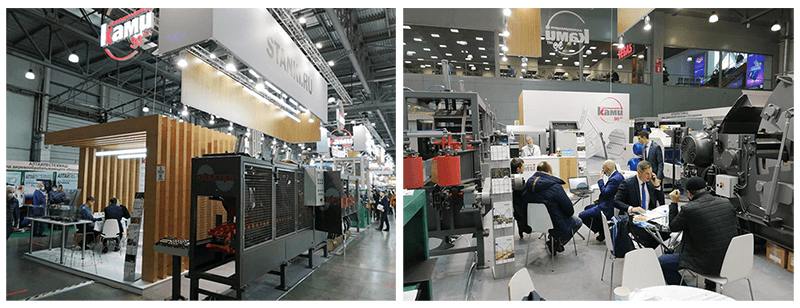

Exhibition

Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood production line

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.Door to door service is possible.

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close