Finding Solutions for your automated wood veneer production!

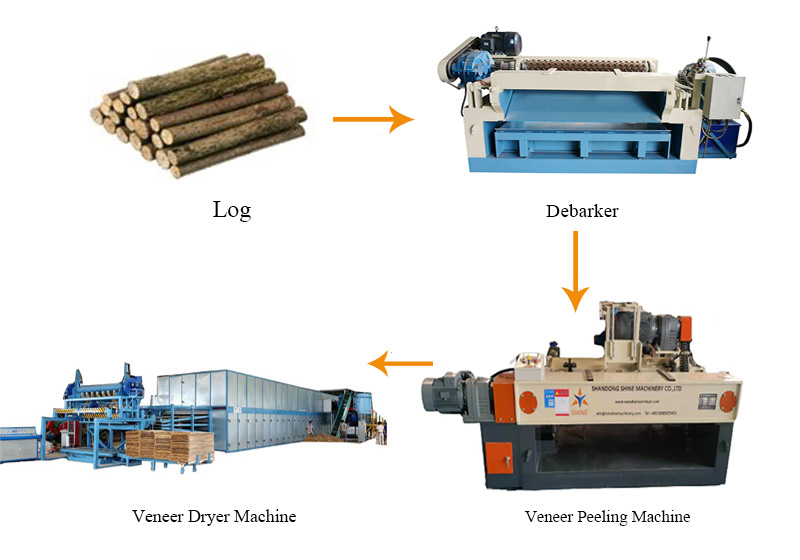

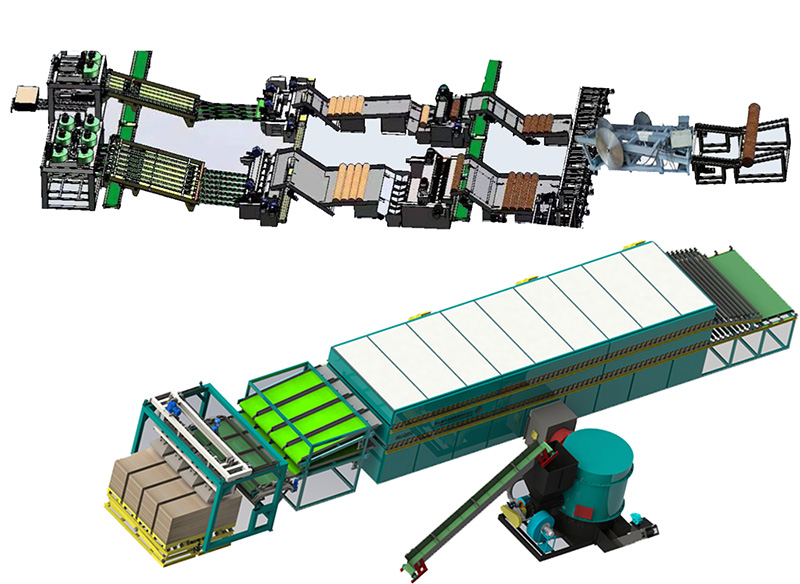

The production of veneer consists of several parts, from log handling, to rotary veneer peeling, to rotary veneer drying. Shine has perfected each step of the production in terms of the technology and processing to produce the most optimal veneer needed. Shine Machinery is suitable for all wood materials to produce veneers.

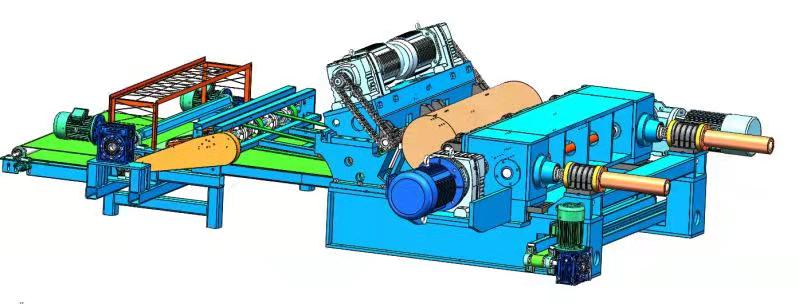

Shine's rotary veneer cut line provides different models of equipement, from medium equipment to high equipment, including log feeder, debarker, veneer peeling machine, veneer stacker, knife grinder etc.

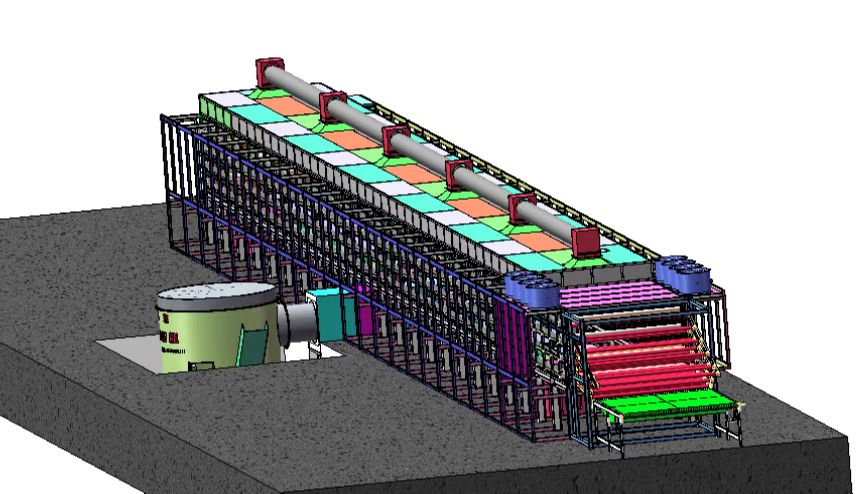

Shine's veneer sheet dryer owns various patented technology, its roller veneer dryer adopts the latest automated drying technology, which the R&D made the entire opertional power decrease by 35%, the core veneer drying is being energy efficient and bring great value to customers. Shine's Biomass Burner could burn both dry and wet waste wood, greatly reduced the buring cost of biomass drying.

Product Details

Shine has been delivering lines and machines for veneer sheet. We know the most crucial points of every process phase from log handling to high-quality end products. With us, your veneer production process starts with the market’s most precise and effective log handling.

Features of Shine Machinery for Wood Veneer Production:

Selectable Level of Automation:

Fully Automatic & Semi-Automatic & Manual Working

Flexible Equipment:

Medium equipment & High equipment & Optional equipment

Diverse Heating Source:

Biomass Burner; Thermal Oil; Steam; Gas

Selective Electrical Components:

International branded components

Customized based on Regions:

Depending on seasons & local production conditions

- Technical Parameter for reference (e.g. 2 deck 48 meter Roller Veneer Dryer)

Model No | GTH30-48 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ 89 special shaft tube |

Heating area length | 44m |

Cooling area length | 4m |

Veneer thickness and size | 1mm-6mm |

Veneer water moisture | 25-30% to about 8-10% |

Heating material | Biomass Burner(waste wood) |

Drying capacity (m³/day) | 80cbm per day |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 5.5KW (11pc) |

Power of Traction Motor | 7.5KW, frequency control (2pc) |

Power of Cold air blower | 5.5KW (1pc) |

Power of 6T Biomass Burner | 16.5KW |

Total Power | 97.5KW ( entire energy saving 35%) |

Actual electricity consumption | About 60kwh per hour |

Overall Dimension(L*W*H) | 52m×4m×3m |

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close