2-Deck Wood Drying Machine of Excellent Drying Capacity

(1)Compared to thermal oil and steam, our biomass burner has a higher heat exchange efficiency.

(2)On the basis of ensuring production output, a smaller power axial fan motor is adopted, greatly reducing power consumption.

(3)Reasonable roller diameter and roller spacing ensure both the air intake and the flatness of the veneer.

Product Details

Product Introduction of 2-Deck 40-Meter Roller Veneer Dryer

Our 2-Deck 48-Meter Roller Veneer Dryer has the advantages of high productivity and low electricity cost .

The main body of the dryer adopts a 5.5kW axial flow fan. Compared to an 11KW centrifugal fan, it has lower energy consumption and larger air volume. With other configurations unchanged, the dryer using an axial flow fan can save approximately 35 kWh of electricity per hour.

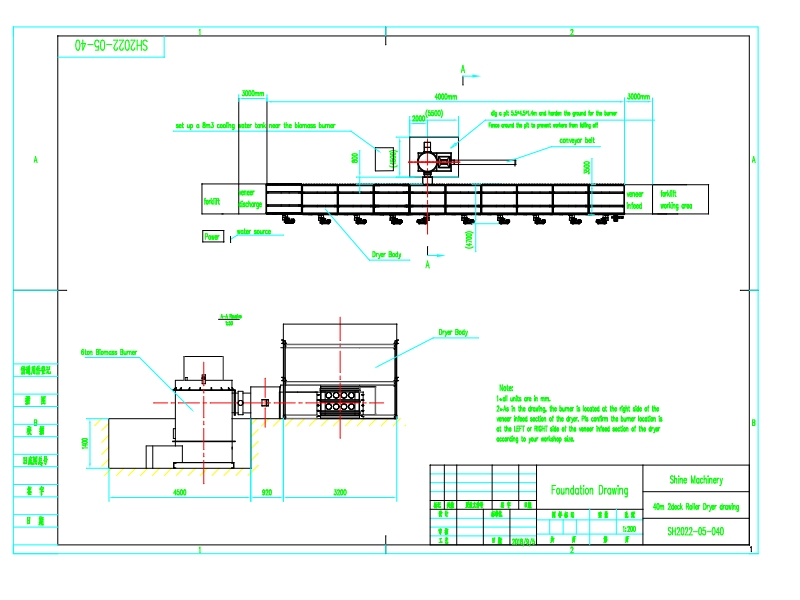

Layout Drawing of 40 m Veneer Drying Machine

Product Parameters of 40 m Veneer Drying Machine

Working Width | 3m |

Deck | 2 |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 108.5KW |

Actual electricity consumption | About 70kwh per hour |

Project Case

Roller Veneer Dryer of Indonesia

Our Certificate

Our Services

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory.

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment.

5.Train the first-line operator.

6.Provide the VIDEO with Install and debug the equipment.

7.Provide technical exchanging.

8.Door to door service is possible.

Product Packaging And Transportation

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close